History

Our Journey Towards A Better Tomorrow

GEMSCAB has been serving an assortment of industries for over 40 years now. During this time, our company went beyond its call of duty to create maximum client satisfaction and retention with our state-of-the-art services. Over the years, the stakeholders persisted in evolving and strengthening, which has helped us improvise on our high-value orders.

GEMSCAB has always driven its strength to innovate through evolving market needs. By adapting to these changes with an ethos of endeavour, we succeeded in building a robust business just in time. These factors acted as a driving force to help us establish better services on our manufacturing grounds at Biwadi and Pathredi, Rajasthan.

With time, the latest technologies and advanced machinery were introduced into these manufacturing regions, which encouraged our team to plummet into other untapped sectors too. Today, GEMSCAB contains a powerful line-up of professionals who are career-driven and visualise a more progressive future for our customers, available through our contemporary cable services.

Who We Are

We at GEMSCAB work in tandem with our customers

From diverse markets to design, manufacture and test our products to various demanding specifications. For us, quality , prompt delivery and competitive prices assure customer satisfaction, our strongest defence against competition and the only path to sustained growth and earnings. It is our progressive corporate culture which allows us to develop and leverage our knowledge, skills, imagination and courage so that a dynamic and result oriented organization is created.

Every worker within our company is a team player. GEMSCAB increases their potential for development in the company. The company rewards personnel for excellent contributions to its business. It is in this context that we have formulated our HR Policy, which ensures that:

All employees are provided with equal opportunities & challenges and the staff are provided with a safe and healthy work environment and it also enables employees to perform their work efficiently and at the same time provides the flexibility to attend to family and personal responsibilities.

Every effort is made to achieve and maintain effective two-way communication at all levels of management.

We at GEMSCAB have been associated with marketing

and manufacturing of electric cables over a period of 4 decades now.

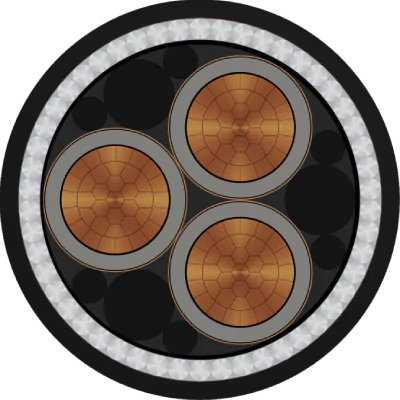

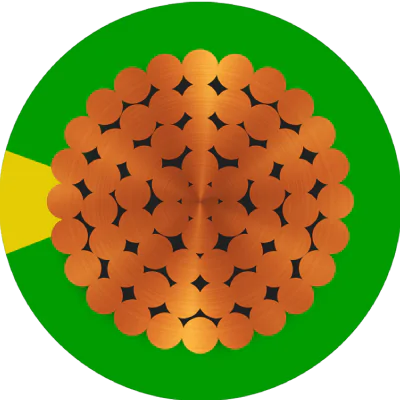

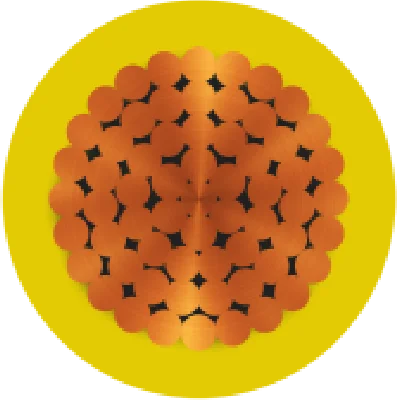

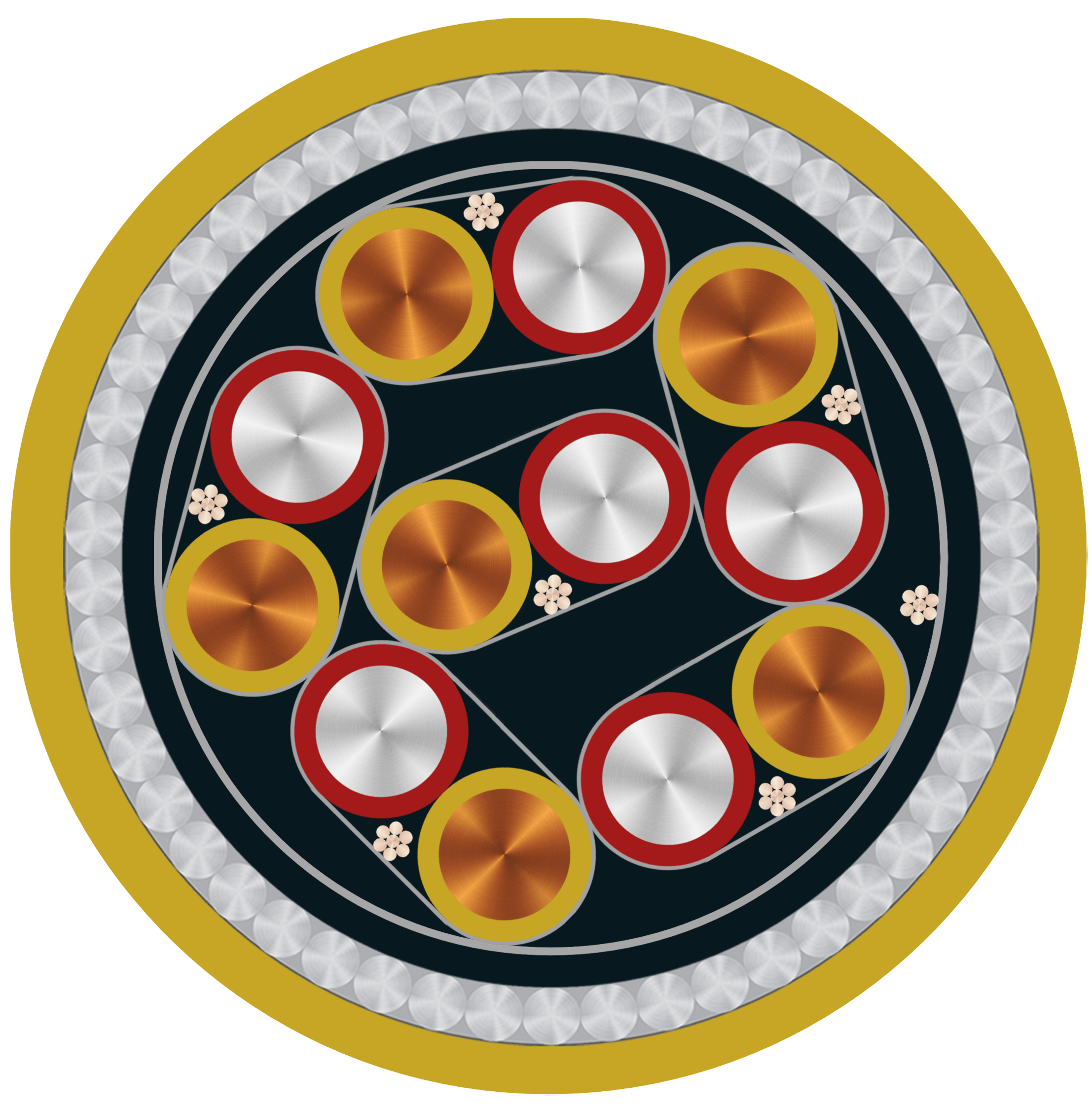

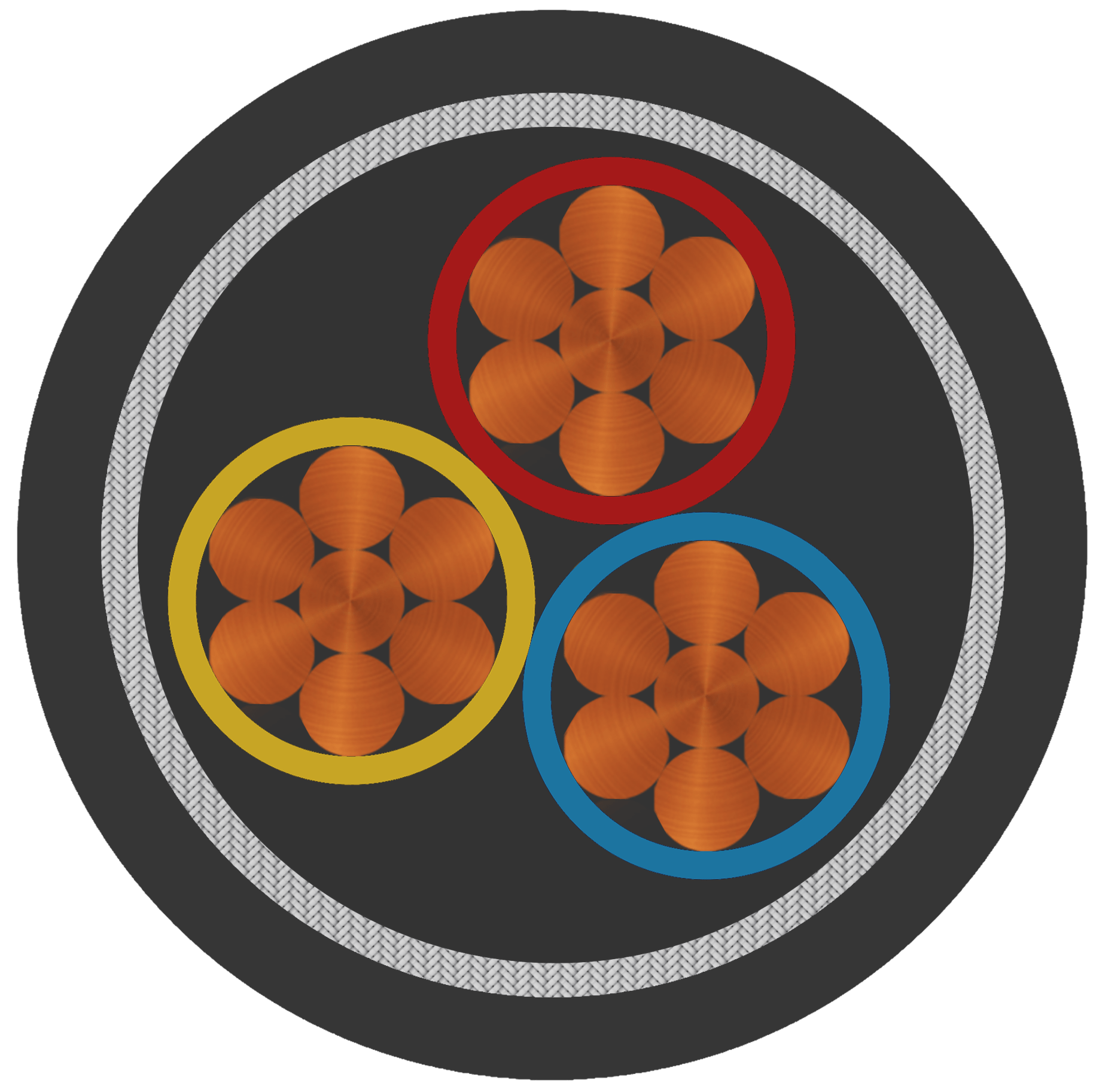

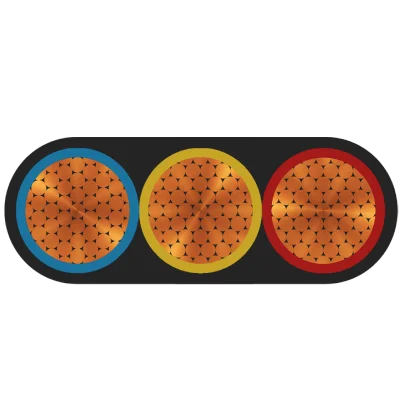

Over the years GEMSCAB has developed a wide range of specialized cables to address the specific requirements of industries involving modern process technologies, instrumentation and communication.Customer satisfaction has been our prime focus and we have strived to provide and achieve the same by adapting ourselves to changing scenario, technology and financial needs.

We are proud to have succeeded in creating a pool of resources to provide quality products and services and execute large volume and value orders in a shortest period at our manufacturing plant at BHIWADI (Rajasthan) and DELHI.

GEMSCAB has been growing during the last 5 years at a consistent growth rate of above 80% and is expected to grow further in the coming years by increasing its capabilities.

Management Team

GEMSCAB is handled by a board of directors that compromises

of well qualified professional from engineering & management disciplines with cutting-edge experience in the cable industry.

The directors work in close coordination with each other and with highly experienced professionals at the helm of every department.

We believe that such a multi-skilled and multi-disciplinary team brings creativity, quality and efficiency to our processes, decision making and execution.

OUR Vision

Customer Satisfaction Is Our Foremost Priority

We envision a future where environmental consciousness and sustainability are at the forefront of our operations. We are committed to being a driving force in the industry, leading the way towards a greener and more sustainable world. Our vision encompasses every aspect of our business, from sourcing raw materials to the manufacturing process and product lifecycle. We strive to minimize our environmental impact by implementing innovative practices, embracing renewable energy sources, and reducing waste generation. Through continuous research and development, we aim to create technologically advanced cables that not only meet industry standards but also contribute to energy efficiency and conservation.

By prioritizing environmental stewardship and sustainability, we are dedicated to providing our customers with reliable, high-quality cables that empower them to build a brighter and more sustainable future.

GEMSCAB's

Quality Policy :

- CONFORMANCE TO REQUIRED PROCEDURES AND QUALITY ASSURANCE PLAN

- CONTINUOUS IMPROVEMENT IN QUALITY TO ACHIEVE CUSTOMER SATISFACTION

- UPGRADATION OF HUMAN RESOURCES, THROUGH KNOWLEDGE AND SKILLS

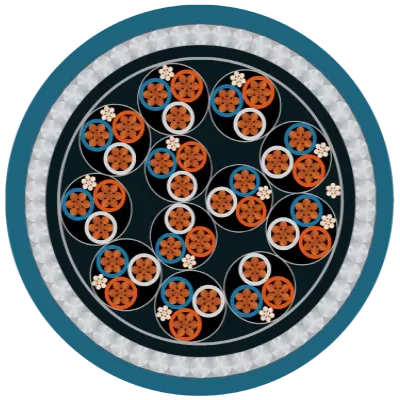

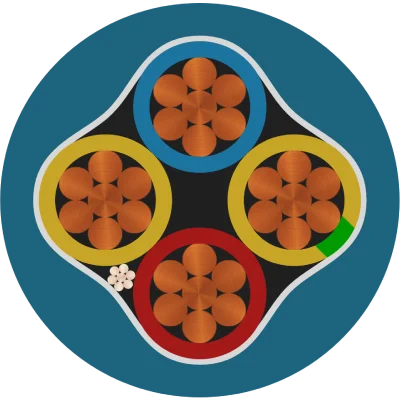

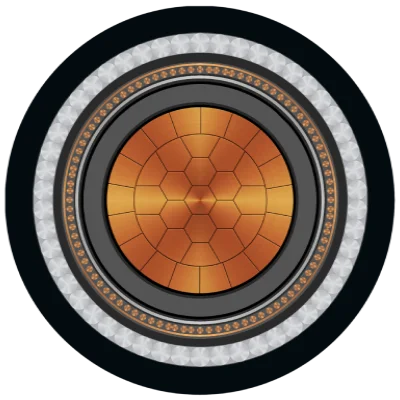

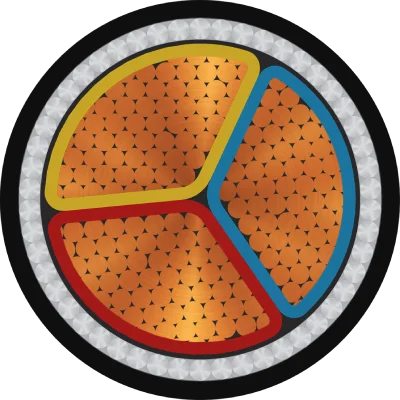

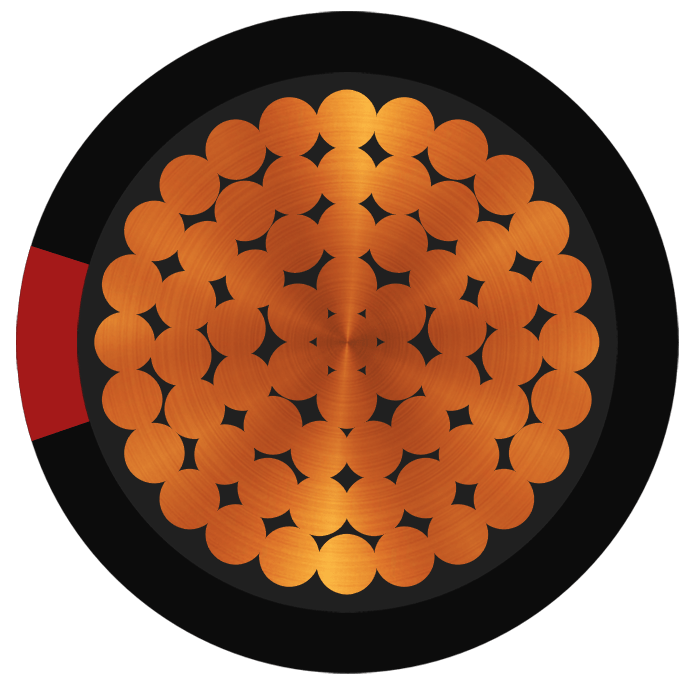

GEMSCAB manufactures cables as per various Indian / International standards and specializes in producing cables for critical application. The cables are designed after detailed engineering to meet the specific requirements and give high performance reliability while in service.

At GEMSCAB, the quality is the core issue and principal of our company philosophy National / International norms are applied rigorously and consistently in all our designs, manufacturing, testing of incoming raw material and finished goods as per various National / International standards viz BIS / BS / IEC to guarantee an optimal quality in our products and services.

Our laboratories are equipped with modern and computerized testing equipments to carry out testing in agreement with the National / International standards to suit our customer’s requirements.

Our systems are designed to achieve our main objective of providing maximum quality and to support it with the best service in the market.

The company has been accredited with ISO : 9001 : 2008 and ISO : 14001 : 2004 and OHSAS 18001:2007 certification by SYSTEM MANAGEMENT REGISTRATION CO. LTD. and KBS Certification Services Pvt. Ltd. in addition to the approvals from various National & International Organisations.

The tryst for continuous quality improvement is never-ending in GEMSCAB. We always strive to maintain high quality standards, which help us fulfill our mission to povide world class information, technology solutions and services, to enable our customers to serve their customers better.

Our Roadmap To Sustainable Quality and Excellence

At Gemscab, we’ve adopted a numerous sustainable procedures. Our three windmills have a combined capacity of 2.85 MW and produces about 3,700,000 units of electricity yearly. Furthermore, our rooftop solar power plant, which has a capacity of 704 KWp, generates approximately 900,000 units of electricity annually. Additionally, we intend to increase the capacity of our solar plant by 750 KWp.

In order to minimize our carbon footprint and further reduce our impact on the environment, diesel-powered boilers have been replaced with gas-powered boilers. Furthermore, energy-efficient compressors have been installed, and all machine drives have been modified from DC to AC. Moreover, to achieve a power factor of 0.99 and higher, we have also installed capacitor banks in our APFC panel and replaced conventional AC units with energy-efficient inverter technology ACs.

Leveraging recycled water for cable cooling during extrusion, installing zero discharge facilities and water harvesting systems at both of our manufacturing facilities are all examples of how we prioritise water conservation.

We have significantly improved our infrastructure by replacing asbestos/cement plant sheds with aluminium sheets, installation of transparent roof sheets for natural light and ventilation, and installation of LED lights throughout our plants. We have transitioned to utilising battery-operated handling equipment for internal transportation, reducing our reliance on fossil fuel-powered machinery.

We ensure responsible environmental management by upholding pollution standards and implementing emission-reduction plans. Our master batches are lead-free and RoHS-compliant, demonstrating that our dedication to sustainability extends to the materials we use. We place a high priority on ethical sourcing and only buy raw materials from non-conflict areas. Both hazardous and non-hazardous waste are disposed of properly wherein hazardous wastes are specifically disposed of through licensed dealers and processors.

By embracing computerization and digitalization, we are lowering our consumption of paper. By implementing digital workflows and reducing paper usage across all of our operations, we hope to eventually create a paperless workplace. As an integral part of our sustainability efforts, we actively participate in tree plantation practices, diligently planting saplings within our factory premises and the neighboring communities. We take immense pride in the lush green environment created by the presence of over 500 trees encircling our plant, symbolizing our commitment to environmental preservation and community well-being.